Support Bracket

A 5-man team led by myself were tasked with the following:

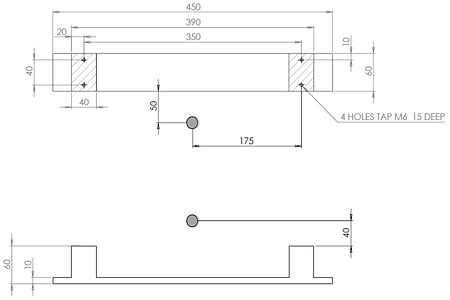

Design a bracket to support a load offset from a fixture

Manufactured by SLS process using Fine Polyamide PA2200

Maximum component size of 380x30x60mm before assembly

Given budget of £150

Team Objectives

Maximise load to cost ratio

Initial calculations would be done by hand

Design would be done using CAD SolidWorks

Finite Element Analysis using ANSYS for iteration development

Theory

Strength to weight ratio calculations concluded I-beam design to be the most cost-effective

Concept

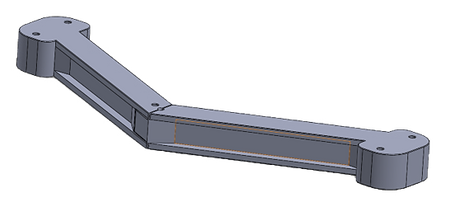

Further from initial calculations the first bracket is made in solid works with the chosen I-beam cross-section

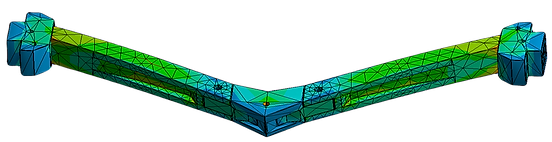

Simulation

Finite-Element-Analysis is then enacted with boundary conditions applied, simulating deformation under expected loads

Quality Check

With limited elements available, meshes are focused in detail along the most significant areas of stress concentration found.

These meshes are further examined and adjusted to accommodate the curved edges, joints, and fillets to produce an overall analysis with respectable element quality.

Refinement

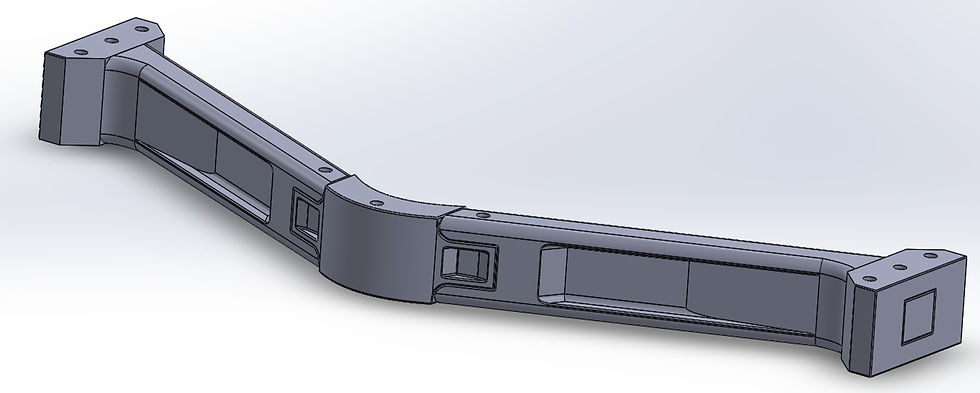

The bracket is then refined and improved where causes of failure are found, and an iterative process of modelling to FEA is enacted to arrive at a final and optimised support bracket.

Final Product

With the successful material reduction and optimisation along each stage, the final product uses 60% of the available budget